Founded in 1958, FAIVRE Group is a French company located in Baume-les-Dames (25), between Lyon and Strasbourg. This French group designs, builds and commercializes aerators, drum filters and industrial pumps for water and wastewater treatment.

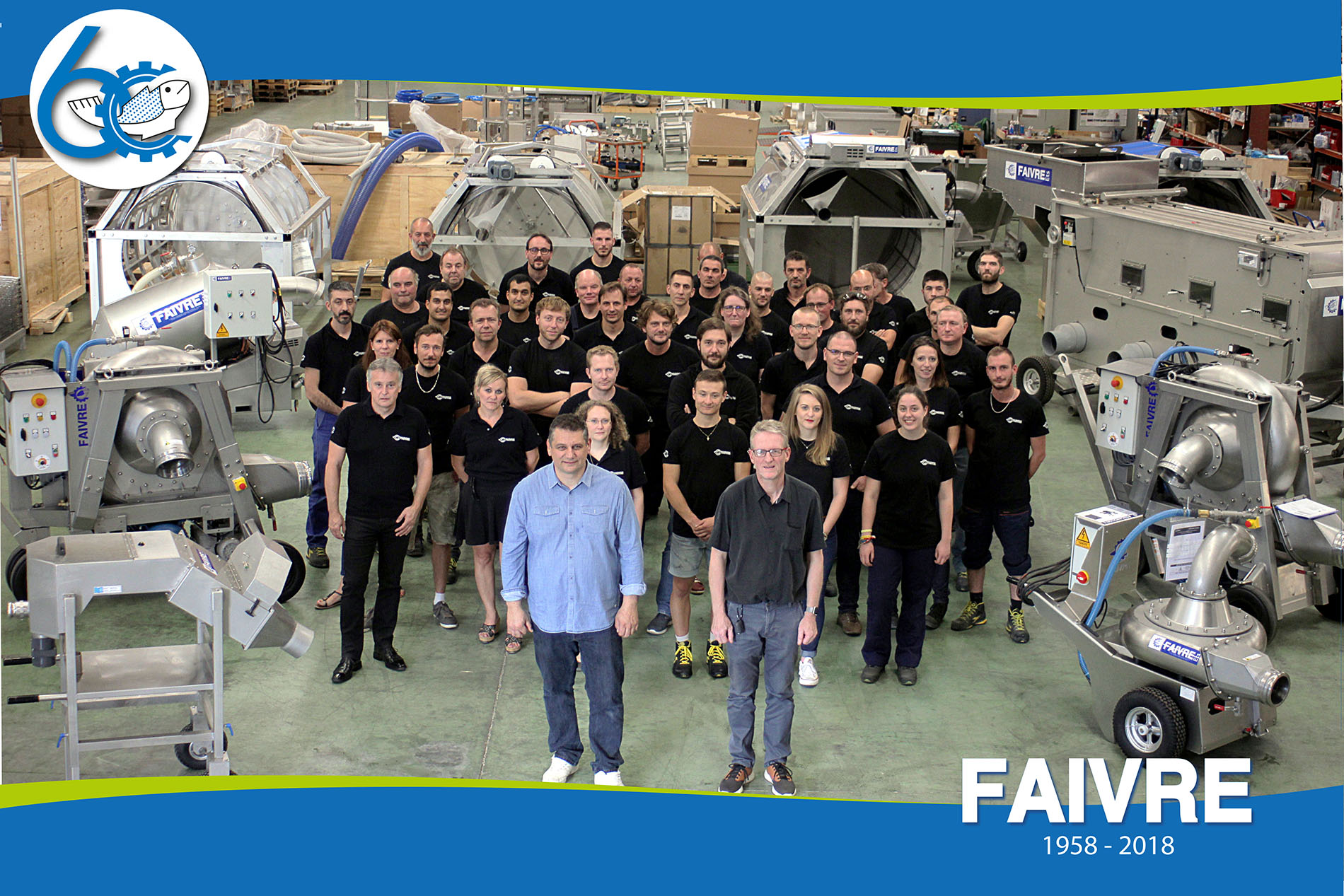

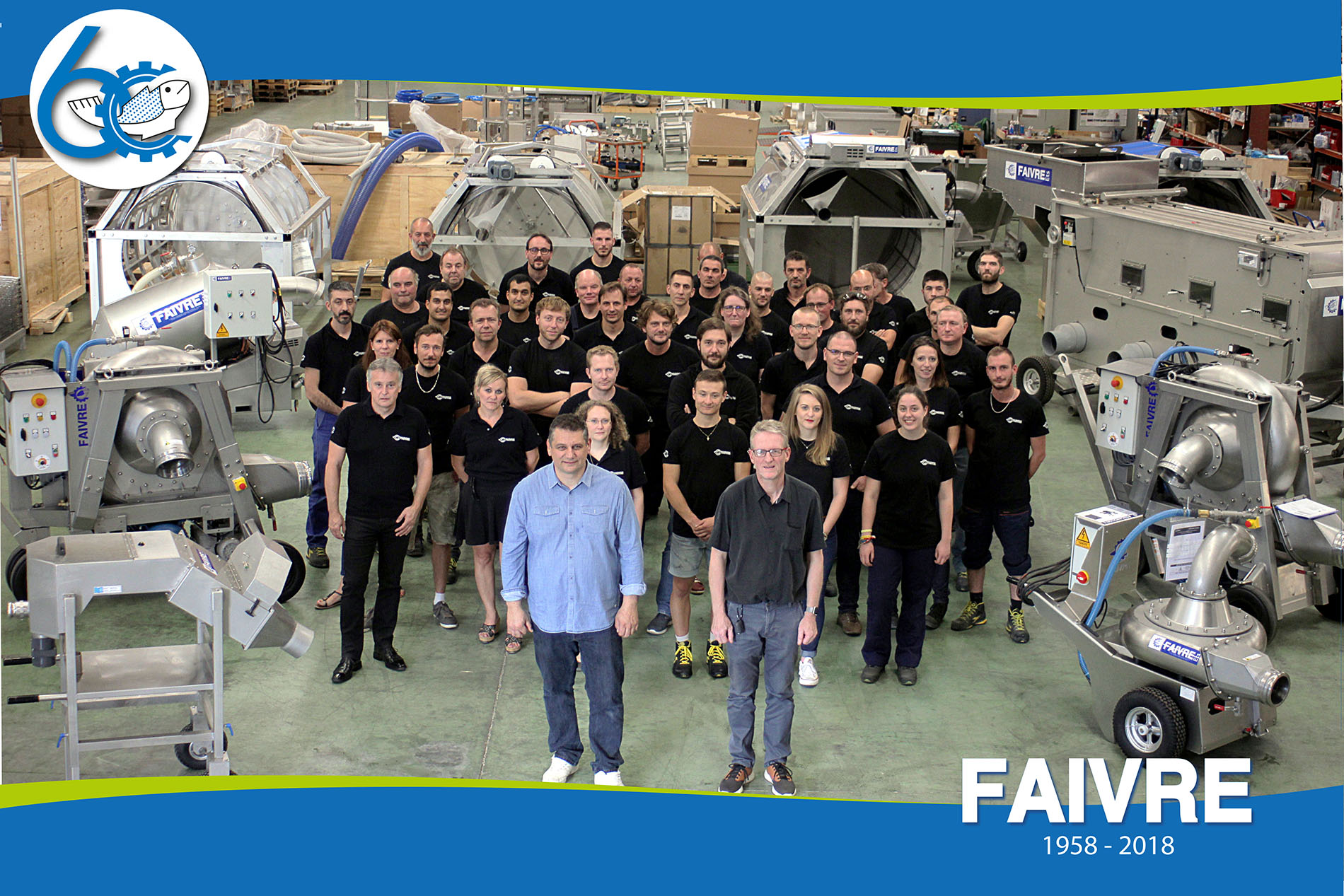

RENCONTREZ NOTRE ÉQUIPE

La société FAIVRE a su s’entourer d’une équipe efficace et volontaire. Chaque demande fait l’objet d’une étude et d’un suivi personnalisé grâce à notre Bureau d’Études, qui met en oeuvre son savoir-faire pour répondre au mieux au projet de chacun. Une équipe de techniciens et de dessinateurs est à votre écoute du début du projet jusqu’à la mise en place de l’installation, pour assurer un service de qualité. Chaque membre de l’équipe FAIVRE Group a un rôle au sein de cette structure familiale et ainsi assure le bon fonctionnement de la société baumoise et permet un suivi professionnel de chaque appareil.

MEET OUR TEAM

FAIVRE Group incorporates a voluntary team. Each inquiry is studied and personalized depending on each project. FAIVRE’s team executes its knowledge and skills to satisfy the customer’s need. Every people of this French company plays a role !

NOTRE

SAVOIR-FAIRE

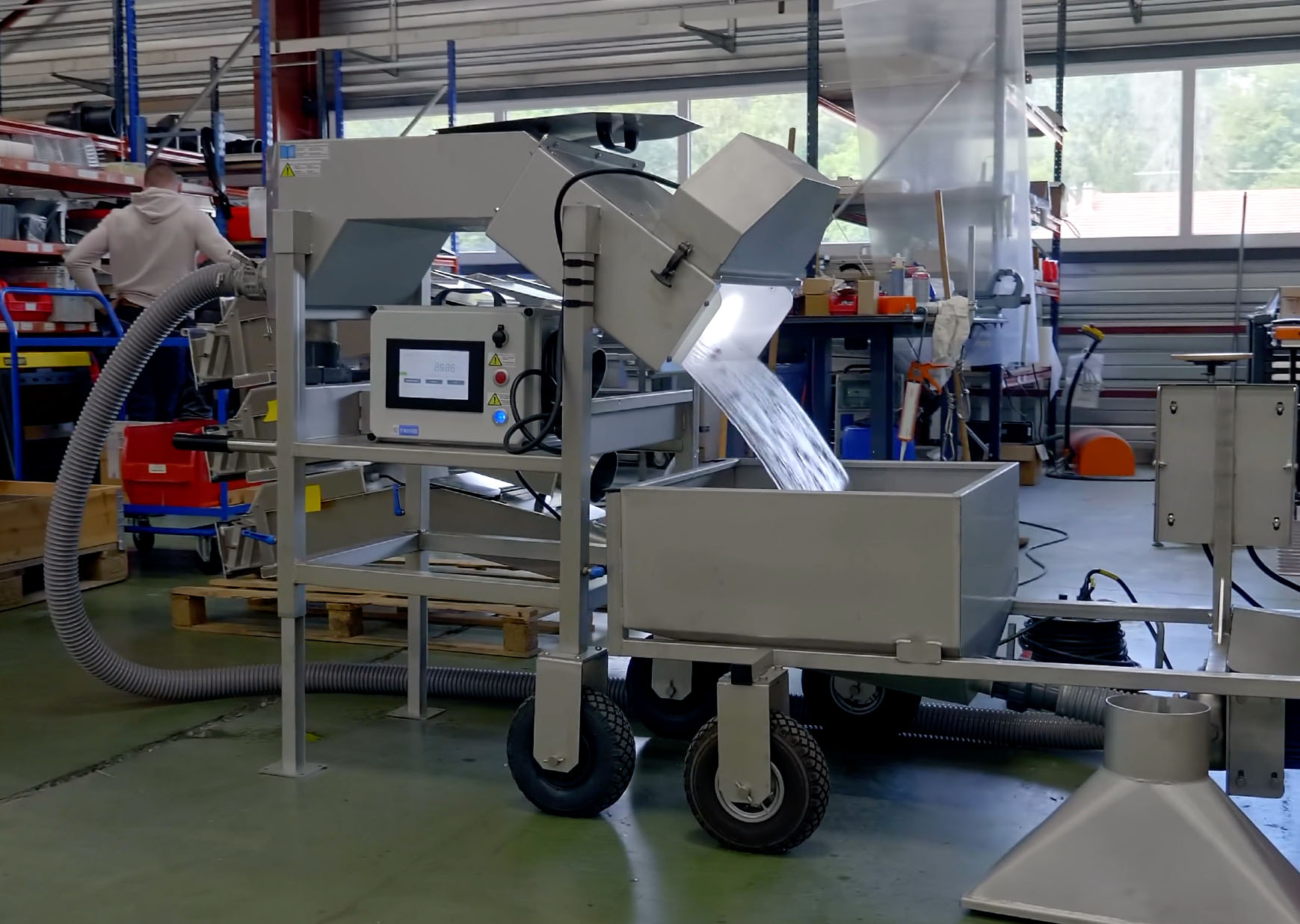

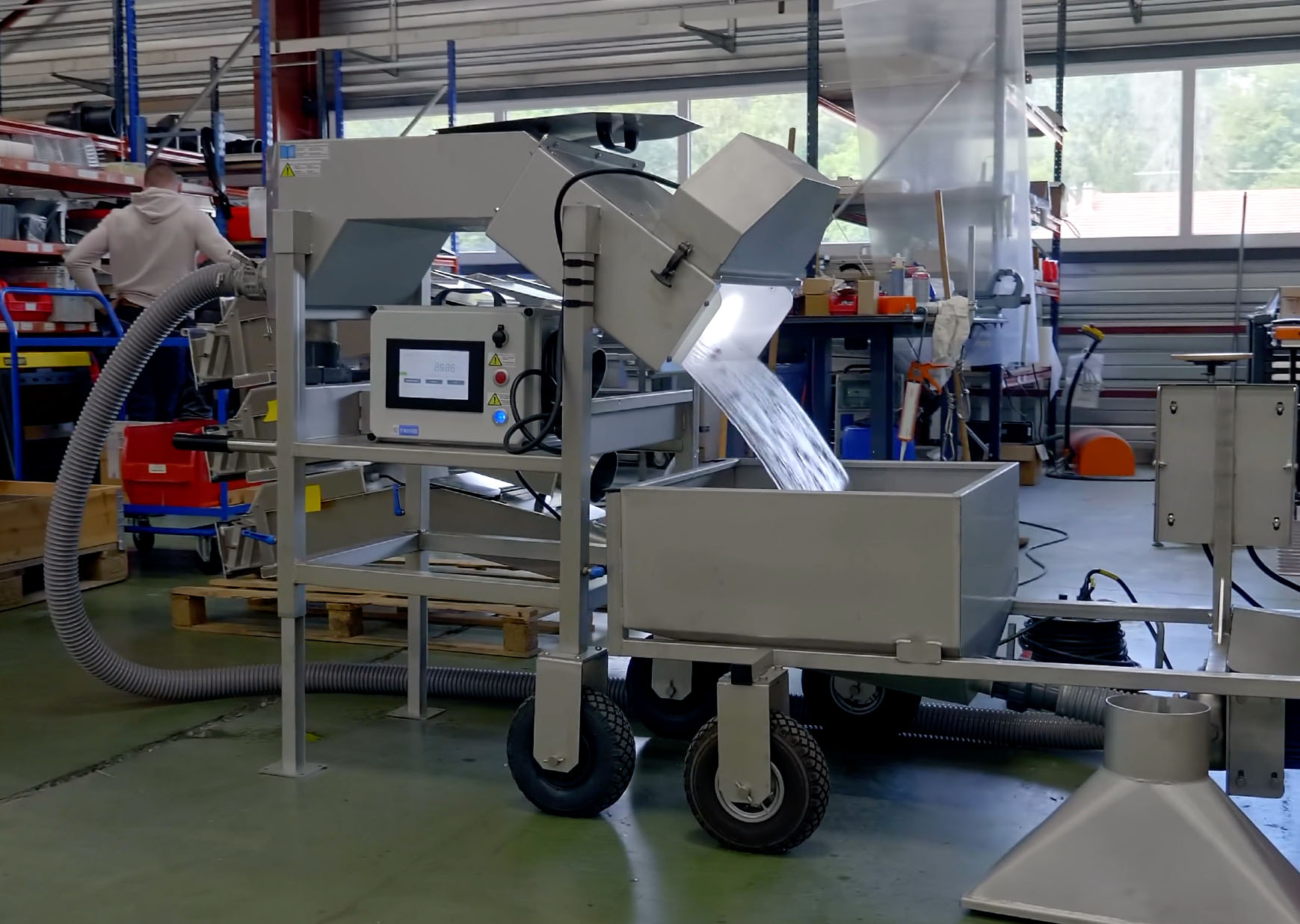

Les équipements de conception et de production sont modernes et performants : conception des machines en 3D, tours et plieuses à commande numérique, découpe laser dernière génération… Après avoir été pensées par le bureau d’Études puis découpées et pliées par nos équipes en atelier de production, toutes les pièces sont assemblées dans l’atelier de montage. Chaque appareil est ainsi monté pour être ensuite testé dans notre bassin pour assurer une machine de qualité, répondant à toutes les caractéristiques attendues. En parallèle, toutes les installations électriques (armoire, section de câbles) des machines sont conçues et vérifiées par notre équipe d’électriciens

OUR SKILLS

Our conception and production equipment are modern and performing : 3D design, folding machine, laser cutting… After being designed by our Engineering office and then cut and folded in our production area, every pieces are assembled in our assembly workshop. Every machines are assembled to be tested in our private pool, to guarantee their quality and performances.

3D Design

FAIVRE Group has its own Engineering office. Every steps necessary to the conception of the machines are essential to warranty the production of the different products.

Laser cutting

This will enable to cut the material according to specific needs. It is the first step of production.

Deburring

This step is useful as it gives a smooth aspect to pieces that come from the laser cutting step.

Machining

Turning and milling is another step of production. This allows the machining of mechanical pieces according to the drawings coming from the Engineering office.

Folding

Folding helps to deform raw materials to give them a well-defined aspect. Once again, this step is realized according to the Engineering office’s drawings.

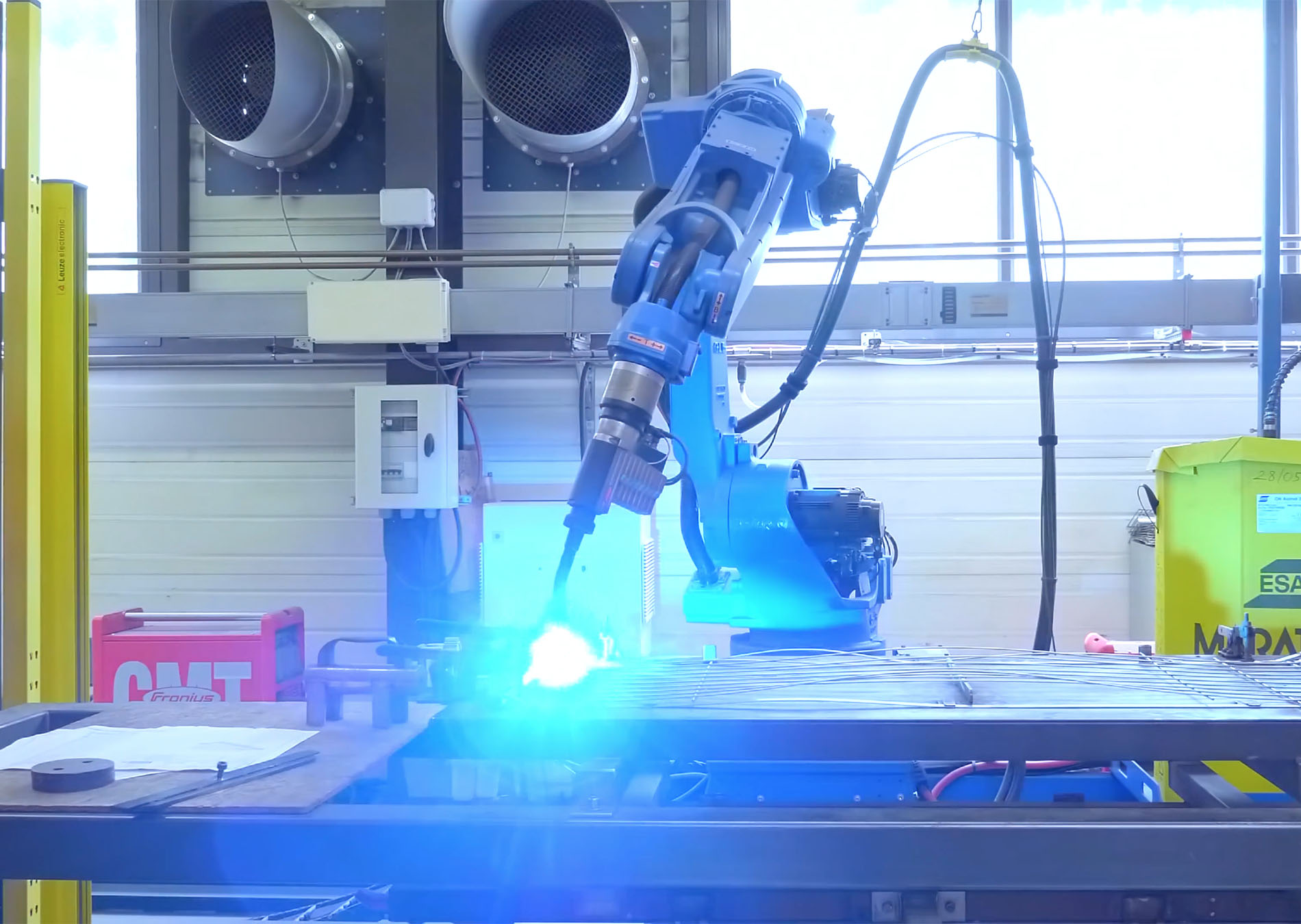

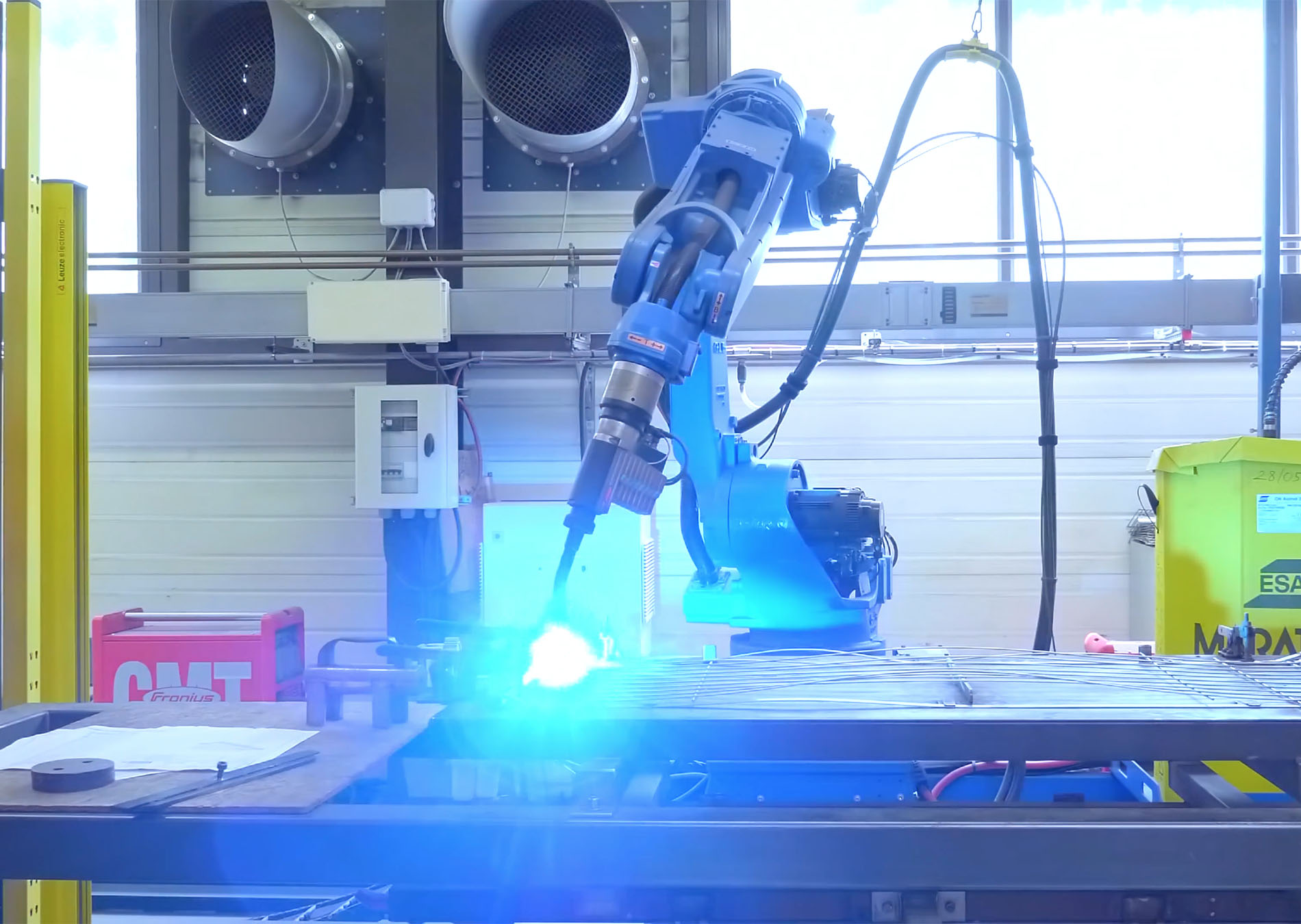

Weld

This is one of the last steps to produce a machine. Indeed, it enables to assemble the different pieces which then will be assembled in our assembly area.

Assembly of pieces

This step takes place in our assembly workshop. The different parts that have been cut, folded and welded are then assembled to create the final product.

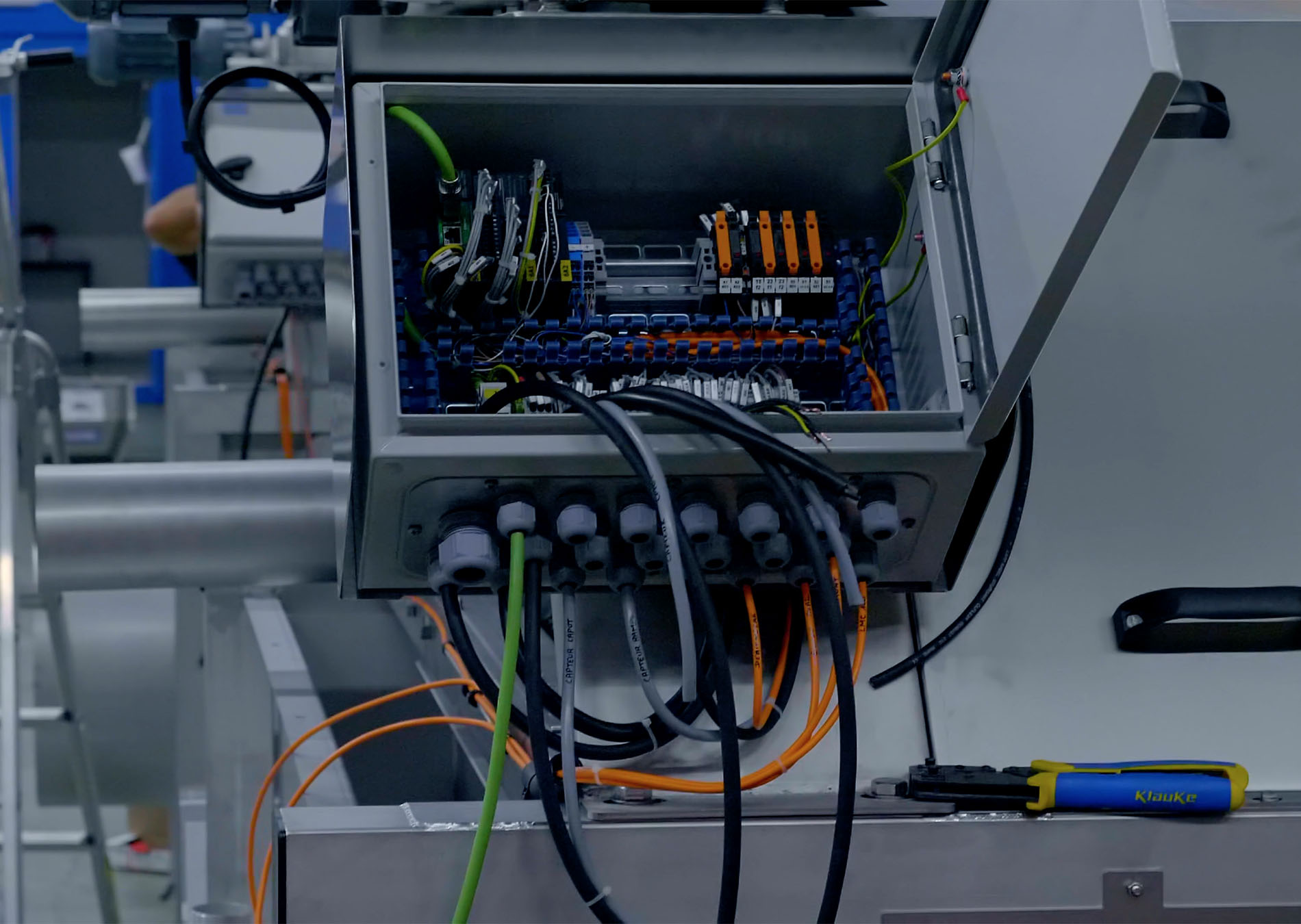

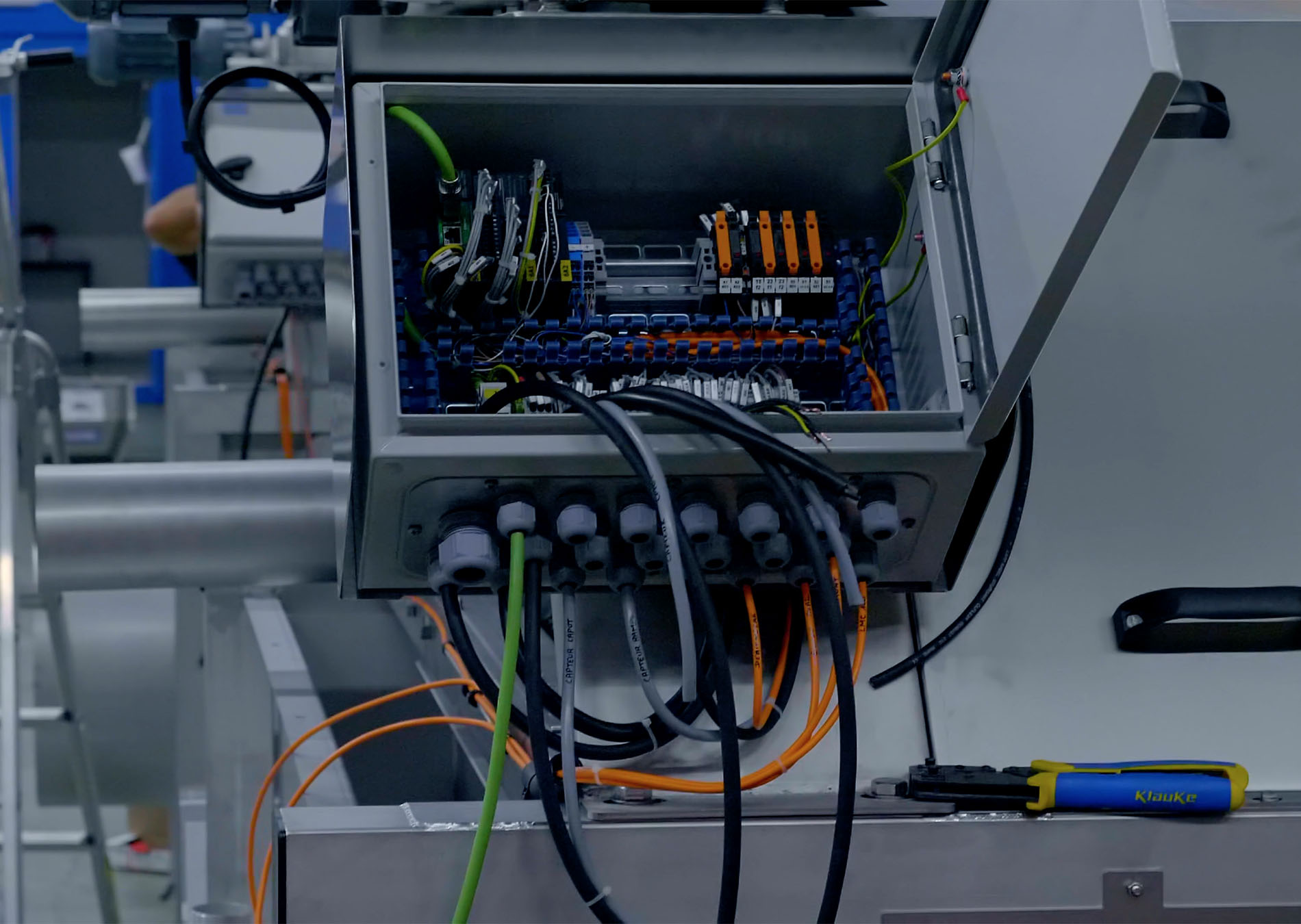

Electricity

An electrician team ensures the starting-up of every machines.

Test bench

Once the machines assembled, they are tested in our warehouse to guarantee their quality and performances. This step is very important as it is to ensure our machines’ reliability and robustness.

Test bench in our private pool

Some of our machines shall be tested into a pool to recreate the environment where they will be used. The machines tested in our pool are mostly aerators, industrial pumps and smaller drum filters. Once again, this is an important step before the delivery of our machines.

UNE HISTOIRE

DE FAMILLE

À l’origine de cette création se trouve Claude FAIVRE, un pisciculteur qui voit son activité se développer. Afin de facilité son travail, M. FAIVRE décide alors de mécaniser sa production et ainsi de créer des équipements pour l’aquaculture. En 1961, il démarre son entreprise dans l’atelier du moulin familial. Très vite, la structure de 300 m2 s’avère être trop petite. Alors, en 1973, Claude FAIVRE décide d’installer son entreprise à Baume-les-Dames, dans une usine de 800 m2, qu’il fait lui-même construire. C’est en 1966 que le premier aérateur flottant à turbine, qu’on appellera «Flobull», fait son apparition. À la suite de cette innovation, l’entreprise se voit évoluer, réalisant alors 30% de son chiffre d’affaires à l’export. Soixante ans plus tard, c’est plus de 80% du chiffre d’affaires annuel de la société qui sont réalisés à l’étranger. En 1993, Claude FAIVRE décide de développer sa société en créant des machines pour un autre secteur d’activité : le traitement des eaux usées. Depuis, plus de quarante employés participent au développement de cette entreprise familiale et ont permis à de nombreux autres équipements de voir le jour, permettant ainsi à FAIVRE Group de devenir un des leaders mondiaux dans son domaine!

A FAMILY BACKGROUND

Claude FAIVRE, a French fish farmer, sees his activity increases. In order to facilitate his work, M. FAIVRE decides to mechanize his production and to create equipment for aquaculture.In 1961, he begins his company in a little warehouse and thendecides to settle his company in Baume-les-Dames. In 1966, Claude designs and commercializes the first floating aerator, named “Flobull”. Thanks to this innovation, the company begins to be renowned overseas. It is in 1993 that M. FAIVRE decides to develop another activity by creating machines for water and wastewater treatment. Nowadays, forty people are employed in this family business and participate to the company’s development.

Corporate foundation

First floating aerator – Flobull (patented)

Company’s development – Creation of FAIVRE Industrie

Creation of the water jets Flostyle and the first drum filter Rotoclean

Creation of both ranges of aerators Hydropulse and Flopulse for wastewater treatment

New floating aerator – Flosub

Development of the Rotoclean range – drum filter model 200

First industrial pump – LowMotion 6

Second industrial pump – LowMotion 8

60 years anniversary

Third industrial pump – LowMotion 2.5

Creation of a new range of drum filters – Smart Filter

Besoin d'un renseignementdocumentdevisconseilproduit ?

Notre équipe est disponible pour répondre à vos questions !