According to the customer’s request, an upstream case study might be necessary. Here are some of our studies.

Bad smells released by waste waters

Treatment and storage of industrial or urban residual waters create smelly composites. The bad smells can really disturb the neighborhood.

An odor results from aromatic volatile composites present in the air. During the biological fermentation process, smelly composites are delivered from the waste waters full of organic load. As a result, bad odors emerge.

Many elements from the fermentation of the organic composites can lead to an important olfactory issue:

- ammonia and amino

- mercaptants and sulfurs

- volatile fat acid (VFA)

- aldehydes

Smelly odors emerge when the fermentation process begins into a pond (due to a lack of oxygen). The odors emerge when the oxygen consumed by the microbial activity becomes superior to the natural oxygenation capacity of a pond (I.e the oxygen exchange between the surface of a pond and the atmosphere).

Three factors are responsible for the oxygen consumption, consumed by the microbial activity: the microorganism’s concentration into water, the water temperature and the biodegradable organic load concentration in the pond.

The natural oxygenation capacity of a pond depends on the surface of the basin, water and air temperatures as well as the atmospheric pressure.

An answer to the odor issues

An artificial aeration (via surface aerators) completes the natural oxygenation of the pond by increasing the quantity of oxygen dissolved in the pond and so leads to favorable conditions for the microbial respiration. As a result, bad smells are avoided.

It is important to care about the number of aerators you need as well as their power to optimize the water oxygenation.

Thanks to its experience in waste water treatment, FAIVRE has developed a wide range of aerators. This French company is recognized worldwide and has innovating solutions to resolve aeration and oxygenation issues and to resolve odors issue.

Case study: Sugar refinery Saint Louis Sucre (14)

Background

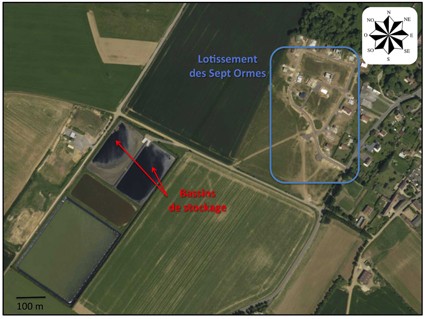

Since 1950, Saint Louis Sucre produces sugar in Cagny, Calvados (Basse-Normandie). Harvested from September to December, the beetroots receive different treatments to extract their juice and sugar. An important quantity of water is necessary all along this process. The water is recycled during the sugar fabrication and at the end of the production (in January) this water full of organic load and rainwater is poured into two ponds (23 000m3) where waters stagnate until the next harvest in the following autumn. Since 2012, Saint Louis Sucre has received complaints from their neighborhood because of olfactory issues due to waste water. In order to fix this problematic, Saint Louis Sucre called Faivre Group.

First study: the emergence of olfactory issue around the sugar refinery

After the analysis of the sugar refinery context, FAIVRE made two assessments. First, the complaints for bad smells resulted from the recent building of a housing estate near the sugar refinery. The proximity between this new housing estate and Saint Louis Sucre exposed the inhabitants to most intense odors. Moreover, this phenomenon was emphasized by important winds coming from south/west-south. Those winds drove the smelly odors towards this part of the village.

Secondly, after a telephonic poll the company noticed that even if waters were stocked since January, bad smells were most present during summer. Two factors were responsible for this problematic:

- the heat which led to the organic load fermentation

- Increase of the inhabitants outside activities.

A temporal approach of the issue

A classic approach would have been to bring a higher oxygen supply when the odor issue appears in June. However, the high quantity of organic load of the ponds (DOC = 10g O2.L-1) as well as the high temperatures of the air and water would need powerful aerators to bring the oxygen supply necessary.

The innovative approach developed by FAIVRE was to treat the issue before the emergence of bad smells by optimizing the degradation of the organic load as soon as the basins were fulfilled in January.

Considering the increase of the outside temperature and the increase of the organic load all along the storage period, FAIVRE estimated the oxygen supply into the basins.

- Without any treatment, the oxygen supply into the ponds double between January and April when the outside temperatures went from 5°C to 15°C.

- By settling powerful aerators in January, a reduction of 60% of the organic load in waters was waiting for April. It corresponded to the oxygen supply twice inferior to those observed when there was an absence of treatment the same month. The aeration power was twice more feeble. This estimation of the oxygen supply in April was inferior to the oxygen supply in January.

These estimations showed that a moderated oxygen supply, adapted to the oxygen supply in January might be enough to decrease the organic load all along the cool period even with a high initial load. When the temperatures become higher, the organic load might be low enough to let the oxygen supply inferior to those of January. Some aerators with moderated power might be sufficient to maintain a level of dissolved oxygen necessary to do not allow the fermentation process responsible for the olfactory problematic.

Solution

In addition to the surface aerators, FAIVRE Group also dimensioned every pond (surface, depth, etc) in order to estimate the length of the electric cable necessary. Moreover, in its specifications, FAIVRE promised that the organic load would be reduced near 95% during summer period in order that the odors issue did not disturb the neighborhood.

FAIVRE also committed itself to deliver an operational installation for the next fulfillment of the basins to do not have olfactory issues the following summer.

FAIVRE found a quick and a ready for use solution.

Analysis after a year of exploitation

Thanks to the installation of the surface aerators in both ponds in Saint Louis Sucre, the organic load of the waste waters decreased from 98% the following summer. The decrease of the organic load was better than expected. Moreover, the neighborhood did not complain for olfactory issues anymore. The objectives fixed before the treatment have been reached. Finally, with this approach, the power necessary for the installation of the aerators were twice feeble than a classic approach because the treatment began in cool period. FAIVRE’s experience in aeration field led to the resolve of the sugar refinery’s olfactory issues.

Conclusion

Oxygenation via surface aerators was a solution adapted to odors problematic coming from the ponds or from residual waters full of organic load. Moreover, this method did not need chemical product and did not create negative impacts for the environment as well.

Water treatment - Aerated lagoon

Water is necessary for the fabrication of many products of everyday life such as sugar, oil, paper… However, to use water contributes to its pollution; it is why remediation treatments must be done to limit the impact of polluted waters on the natural environment.

With the fluid discharge standards, industries must find economic solutions to recycle their polluted waters to avoid juridical penalties.

For over 60 years, FAIVRE Group gives advice to industrial companies to help them resolving issues related to the environment.

A plant oil factory located in Africa called FAIVRE to find solution to treat their effluents.

Context

The palm oil is the main source of vegetable fat. The plant oil mill realizes every step which changes a palm in fruits, fibers, juices, oil, sludge, almonds…

A succession of different steps is made according to the following steps, in order to transform the palm:

- The stalk is collected after being scraped and represents 20 to 25% of the total bunch weight coming into the plan oil factory. Those stalks contain 60 to 70% of water and must be evacuated continuously.

- The effluents are made of condensates, sludge clarification and diverse types of washing and purging steps…

- The risks of pollution are very high into a plant oil mill so it is indispensable to treat the liquid discharges full of organic loads.

Study of the issue

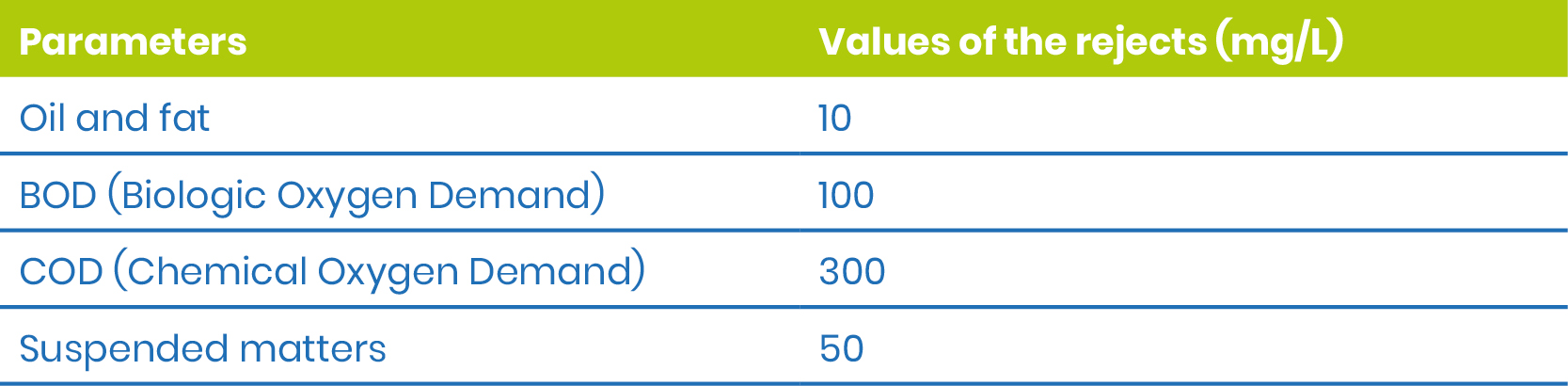

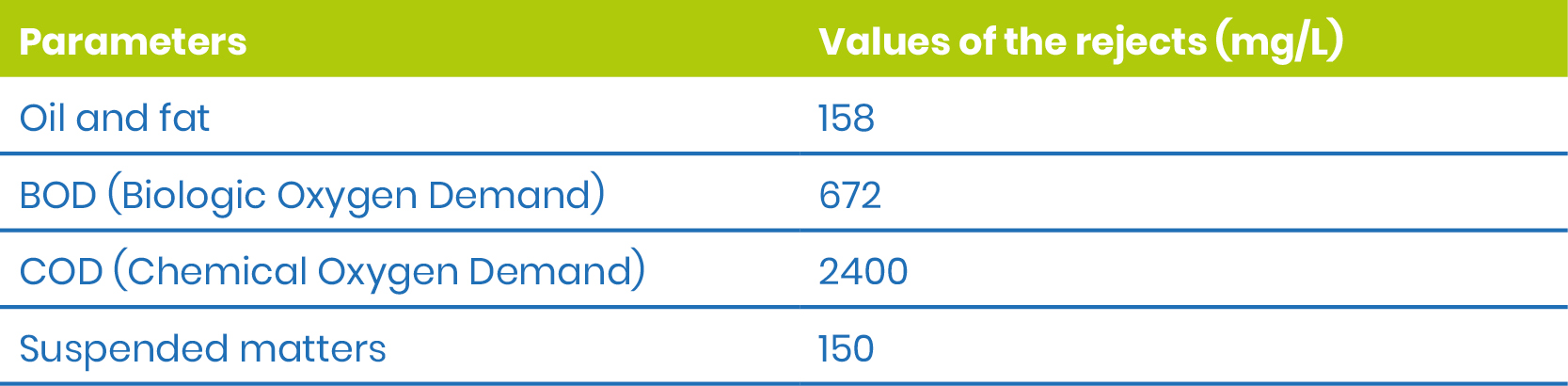

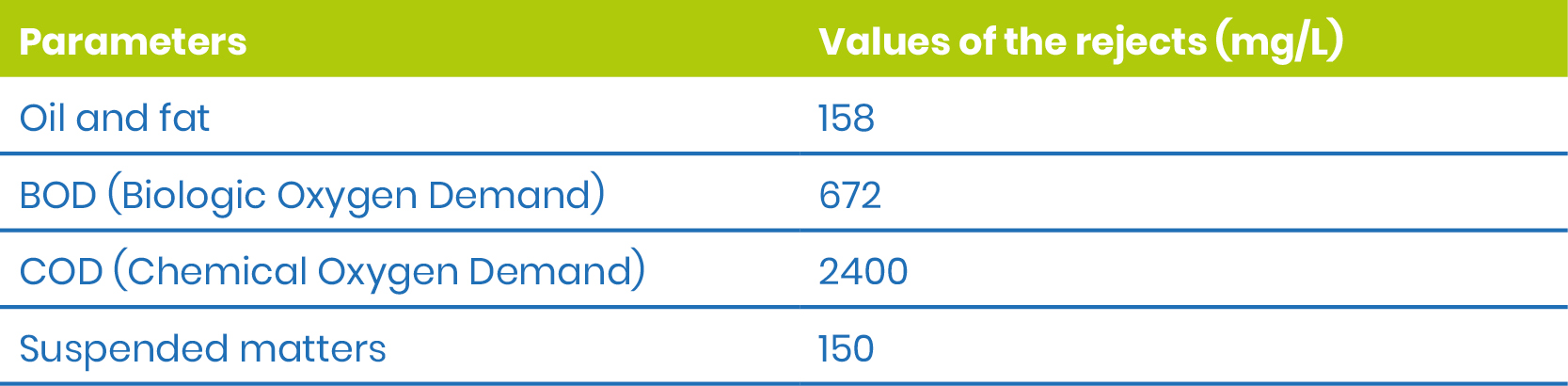

The unity of the palm oil production is submitted to the following fluid discharge standards:

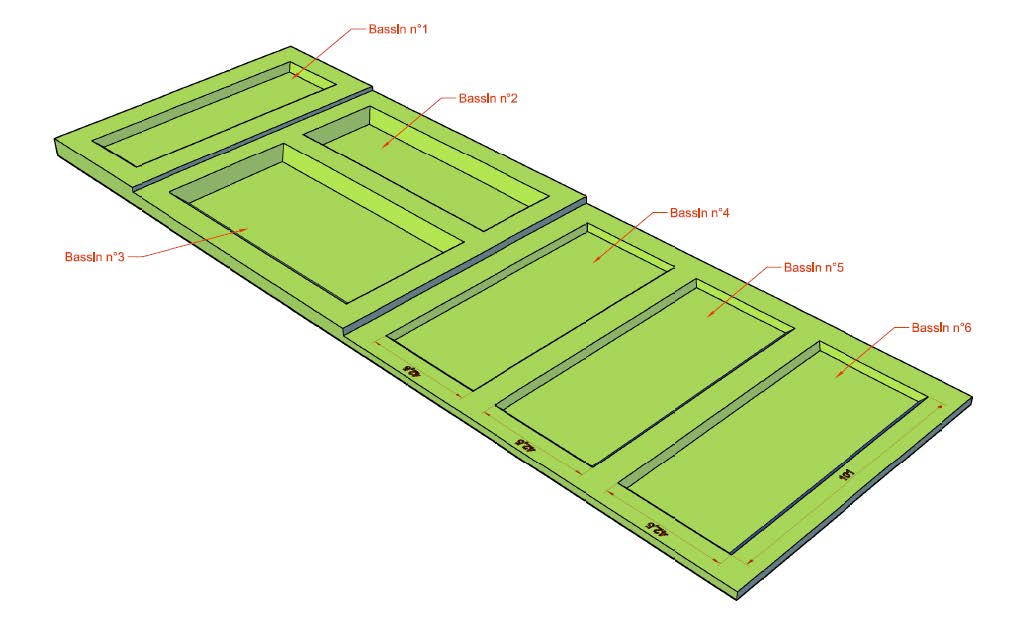

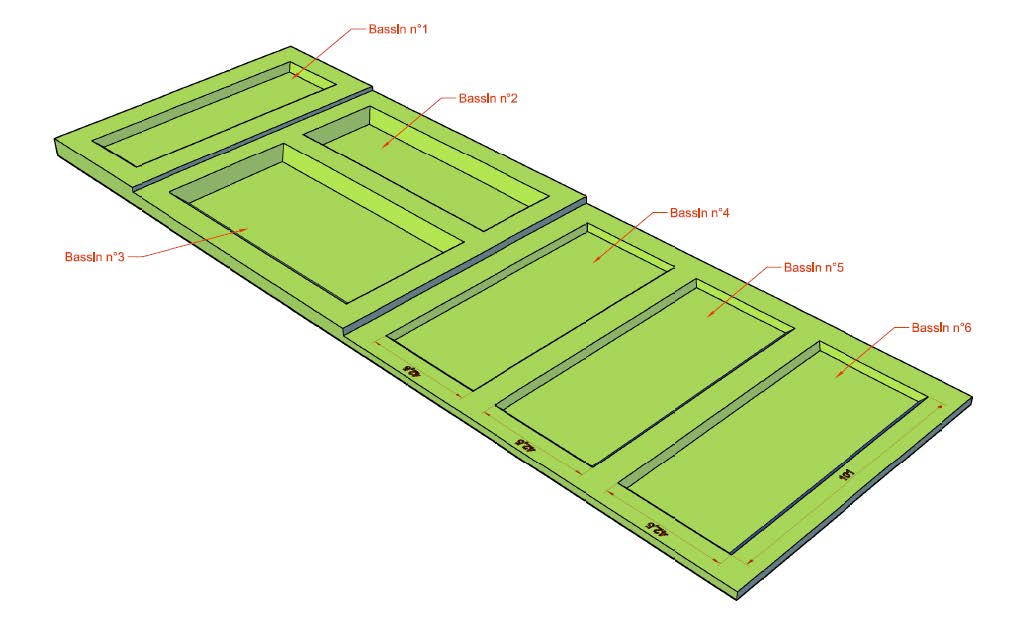

The treatment system is divided in 6 ponds:

- The 1st pond is a cooling pond

- The 2nd and 3rd ponds are anaerobic treatment ponds

- The 4th – 5th – 6th ponds are natural lagoons

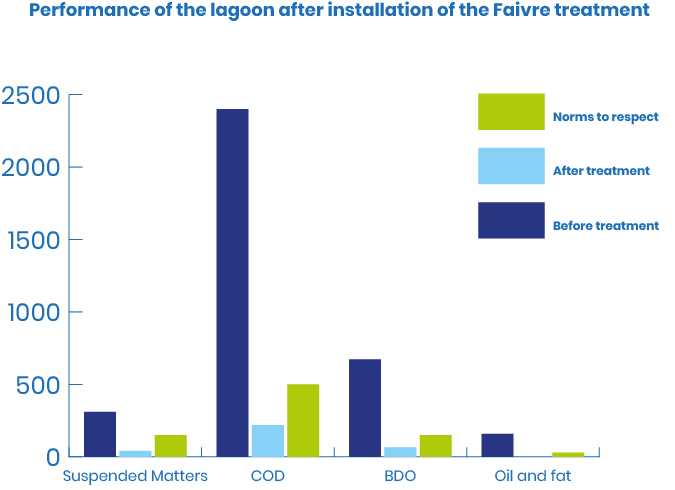

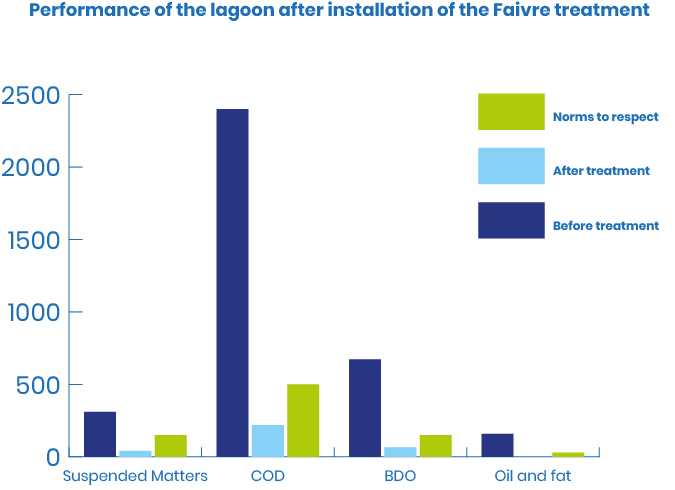

The yield of the initial installation gives the following results:

We obviously see that the plant oil mill is off-standards and the factory must find an adapted solution to treat its waste water.

Measures and advice

This study is about the dimension of the aeration area via some surface aerators on the 4th and 5th ponds while the 6th pond has a decanting role.

The important organic load level coming in the 4th pond has been fixed with the installation of 3 FLOPULSES. The 5th pond (which receives the benefit of purification from the 4th pond) needs the installation of 2 FLOPULSES.

The whole material is settled and exploited during a year.

Results after a year of exploitation

The solution settled by FAIVRE Group permits to the plant oil factory to become on-standards with the following results:

Conclusion

With a purifying yield between 87 and 99%, the solutions brought by FAIVRE permits to the plant oil factory to become on-standards. With an optimized study, only 5 FLOPULSES 44kW are necessary to obtain those results.

Need any informationdocumentquoteadviceproduct ?

Our team is available to answer your questions!